Overview

CT201

A new addition to the EZstrip™ family of products, the CT201 TR Muncher® has been designed specifically to meet on-site tanker discharge requirements and sludge/fat processing, for maceration of solids within the flow and protection of downstream equipment from blockages.

Installation of the EZstrip™ CT201 TR Muncher® is simple, with in-line flanges or the option of tanker coupling connections. Quick release inspection covers also allow in-situ replacement of the cutters, which can be specified to either 8.0mm, 5.5mm and 3.0mm thickness, to match the optimum particle size for specific process requirements.

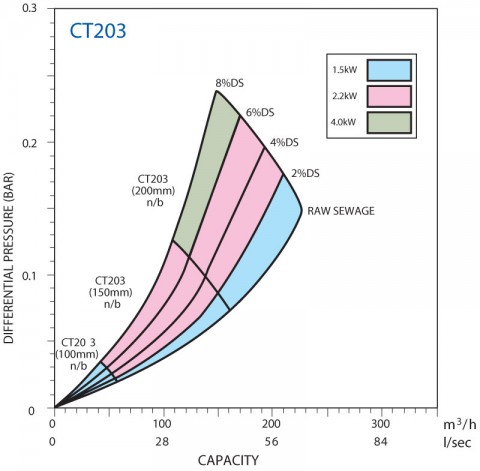

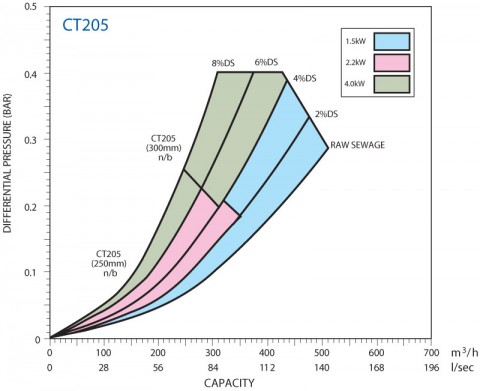

CT203/CT205

Designed specifically for the efficient maceration of abrasive sludges, the EZstrip™ CT203/05 TR Munchers are very effective in capturing irregular shaped objects. The layback cutter shafts on this Muncher are set at an angle to the incoming flow. If a rejection cycle is necessary, the object can drop into the built-in trash trap set clear of and below the cutter stacks, preventing damage. The trash trap is fitted with a large diameter access port to enable easy removal, cleaning and flushing.

| Capacity | Pressure | ||

|---|---|---|---|

| m³/h | 100 (CT201) 500 (CT203/205) | bar | 0.4 (CT203/205) |

| gpm | 440 (CT201) 2,200 (CT203/205) | psi | 5 (CT203/205) |

Applications

| Tanker reception | Pump protection |

| Fat/sludge conditioning | Abrasive sludge maceration – CT203/205 |

| Screenings in wash water – CT203/205 | Organic waste maceration – CT203/205 |